Spirals and Scrolls Part I of Two

Demonstration by Jock Dempsey.

http://www.anvilfire.com

December 15, 1999

guru :

02:39:04

Tonights demo will be about spirals and scrolls. Specifically laying them out and making jigs.

guru :

02:40:40

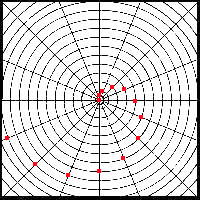

I generally just bend scrolls by eye but many need to lay them out. The easy way is on a grid like this.

guru :

02:42:08

This grid is a set of concentric circles 1/2″ (13mm) apart and divided into right angles, 45’s and 22.5’s

guru :

02:43:11

The scroll is laid out in equal steps. Starting at the center

guru :

02:43:22

guru :

02:44:38

Here we have placed a point on each 90 and 45 degree line moving out one circle at a time.

guru :

02:44:5

guru :

02:46:35

If you put a point on every dividing line as you move out the circles you get a faster more open spiral.

guru :

02:47:06

guru :

02:48:25

But you can also skip more than one dividing line and get a slower tighter spiral.

guru :

02:49:07

guru :

02:51:22

Here we have skipped 2 lines between each point. When we layout the scroll we can divide the “skipped” lines into thirds to make a smoother spiral.

guru :

02:53:34

Using the same grid you can layout any kind of spiral to any scale.

guru :

02:54:49

Once you have your spiral scrolls laid out you will want to make a jig if you need to make more than a few exactly alike.

guru :

02:55:40

There are several methods of making scroll jigs or benders.

guru :

02:55:52

guru :

02:57:32

This simple jig is made of 1/8″ angle iron and 1/8″ by 1″ flat bar. It was used to make identical scrolls in 1/2″ square stock.

guru :

02:58:11

The image is out of shape due to the rectangular image being forged into a square. . .

guru :

03:00:06

This jig was used to make two ends of an “S” scroll that were different sizes. One end was pulled around to a chalk mark roughly at the cross bar, the other was pulled all the way around.

guru :

03:01:07

Using the same jig for both ends gives a pleasing sense of continuity.

guru :

03:01:20

guru :

03:02:46

This jig is made from a forged “fish tail” scroll. The tapering stock forges more naturally into a scroll if you are working by eye.

guru :

03:10:13

The fishtail also sticks up higher than the other parts so that you get the effect of a stepped or progressive jig that can make more than one turn.

guru :

03:11:59

This jig is also welded to a piece of angle iron so that it can be clamped in a vise. Vise mountable tooling is one of the handiest things you can do in the blacksmith shop.

guru :

03:12:24

guru :

03:13:15

This is a scroll bender attachment for a Hossfeld bender.

guru :

03:13:27

guru :

03:14:28

It works by having a hinged portion that swings out of the way so that the bar to be bent can be inserted.

guru :

03:15:52

As the stock wraps around the bender the hinged portion can swing in and a spiral of more than 360 degrees can be bent.

guru :

03:17:27

Normally these production benders produce an ugly flat end on the stock. However, if you are forging a bean end or fishtail on your scroll you can make a bender like this that accepts that style end.

guru :

03:18:34

guru :

03:19:12

Questions?

flatthumb :

03:20:28

looks like the Golden Mean in a spider web – fascinating!

Doug :

03:20:37

Doug, It can be bent hot or cold. Normally the tight center part is bent hot and then the rest cold.

guru :

03:22:46

It takes me about 15 minutes to make one of these and I get $20 for them.

poorboy :

03:21:35

when bending by eye or your first scroll for the jig do you use a set of posts, a bending tool of some sort ?

T-Boat :

03:21:56

the Golden Mean can be found all over nature, flat

flatthumb :

03:22:40

Where did you pick this up Guru? It’s a lot simpler than laying it out with rectangles.:)

joe :

03:23:20

found this a while back, might be of interest..freebie.. GRAPH PAPER PRINTER can be downloaded from the author’s website : http://perso.easynet.fr/~philimar/

guru :

03:23:52

FT, all true spirals are mathematically progressive. Those who try to fit everything into those rectangles are fanatics.

poorboy :

03:24:17

you indicate one of the first jigs you showed us was 1/8″ thick, how heavy of scroll material can be worked on an 1/8″ jig?

guru :

03:25:24

On that jig I bent 1/2″ square. The first 4-6″ were bent hot. The rest cold.

guru :

03:26:10

Most of my scrolls get bent over the horn of the anvil or just curled up hot with a hammer.

guru :

03:27:05

I only make jigs when they have to fit a specific space and you need more than 2 or 3.

Chris :

03:28:13

Hi Guru – I downloaded a picture of that first jig, and don’t quite see how it’s used. Could you elaborate on some of the details?

guru :

03:28:17

The Hossfeld type is expensive to make OR purchase. However, if you are going to make a couple thousand cold bent scrolls it pays off quickly.

guru :

03:28:33

guru :

03:29:34

The “S” scrolls made with this one had to fit existing wooden brackets that made a triangle.

guru :

03:30:17

After scrolling the S’s were fit into a triangular for the final fit.

guru :

03:30:45

This was part one of two. Bill Epps will be doing the second half, “Scroll Ends” in a few weeks.

guru :

03:32:48

These and several other benders can be seen in our Benders article on the 21st Century page.

guru :

03:34:25

If there are no more questions, I’ll say good night folks!