Reverse Engineering a Lathe Drive

When purchasing old or small lathes its not unusual for the line shaft step pulley or backshaft and motor to be missing. Setting this up properly will give you the best performance and possibly prevent damage to your machine by running it too fast.

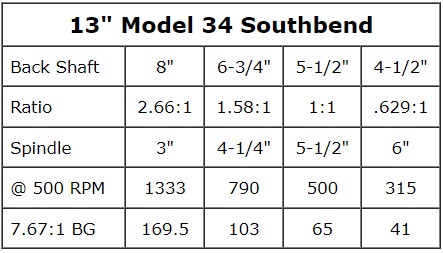

Reverse engineering the facts about your lathe is a handy thing to do as it helps familiarize you with the machine and its capability. If you do not have a speeds chart for your lathe then start by measuring the pulley diameters and calculating the ratios. When there are four steps the ratio between one of the middle pairs is usually 1:1 or very close to it. Thus the spindle turns the same speed as the backshaft at that position. Making your own speeds chart is a good exercise. Spread sheets are REAL handy for this as well.

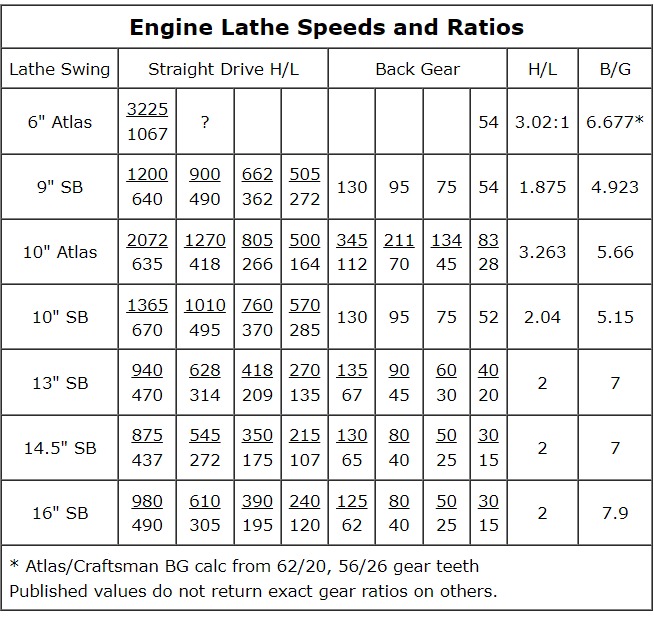

These are some common small lathe speeds. They may give you an idea of where to start setting up your lathe. Note that high range and low range varies between 2:1 and 3:1. These ranges are created by step pulleys between the motor and backshaft or a two speed motor. Note that common two speed motors only have a 1.5:1 ratio and do not significanly increase the operating range of the lathe.

Many older lathes did not have a high range and had either 3 speeds in direct drive and 3 in back gear or 4 in direct drive and 4 in back gear. The proper setup for these lathes is the low range shown above (500 to 1000 RPM max).

For most metal work lathes are not run in the high speed range unless it is very small work. These speeds are for wood, plastics and aluminum.

Broken Back Gears: Many old lathes have the common ailment of broken gear teeth on the back gears. These are expensive to repair and reduces the available speeds by half. Lack of a low range makes it difficult to machine large diameters or chase threads. If your lathe is lacking back gears it may be benificial to setup about one step slow.

Also note that many lathes do not recommend operating them in high range and back gear. Thus instead of being a true 16 speed machines, they are 12 speed.

Note that for practical purposes most reduction by belt is no more than 3 or 3.5:1.

Variable Speed Drives: Often the best way to setup a lathe that is missing the drive is with an electronic variable speed drive. These are available in DC and 3 PH AC. If the drive is replacing broken back gears then it may need a backshaft in order that it runs fast enough to have sufficient torque at the slowest speeds. It is difficult to replace that 5 or 7 to 1 reduction ratio.

Cone (step) Pulleys: When old lathes are moved the backshaft and cone pulley are often left behind or lost. This leaves the lathe with only half the drive. There are several ways to address this problem.

Another method is to use a backshaft driving the large end of the pulley and a motor driving the backshaft through an off-the-shelf set of V-belt step pulleys. Four step pulleys are available off the shelf for small applications. On an 1800 RPM motor this returns 3852 to 840 PRM at the backshaft. This requires reduction of 4:1 between backshaft and spindle. These are roughly the right speeds for an 8″ (200mm) lathe.

Using a 1200 RPM motor and 4:1 at the spindle would reduce the speeds 20%. This is suitable for a 10″ (254 mm) lathe. A 900 RPM motot would reduce the speed again but these are rare difficult to find motors.

Using a common 2 speed 1800/1200 RPM motor in the arrangement above would result in: 963, 770, 680, 544, 311, 249, 210, 168 plus back gear speeds.

The advantage of the above method is that only one back shaft is needed. However, the high speed (3850 RPM) will be hard on the back shaft bearings and requires high speed bearings. To avoid this a second backshaft or a low speed motor is required. In either case this also reduces the amount of reduction needed at the spindle.

The final method is the variable speed motor and controler as mentioned earlier.

LATHE DRIVE: My 13″ Clausing has speeds from 34 RPM in back gear to 575 RPM in direct drive. There is a high speed set of pulleys on the motor & jackshaft, but We NEVER use those. This machine has been in the family for 50 years.

An easy way to make a jackshaft is to use an old motor that has shafts out both ends, the motor doesn’t need to work. If You weld some door hinges on this jackshaft motor so it can pivot and mount the functional drive motor behind it You only have to move the drive motor and it will pull both belts tight. Hinge the drive motor too. This gives quite a range of movement, so pulleys don’t have to match perfectly. My Dad built a drive for a wood lathe this way to get enough speed difference to make anything from porch posts to chair spindles [the lathe was built on a length of channel iron].

– Dave Boyer – Saturday, 08/22/09 21:48:38 EDT

Bench Lathes

When you setup a bench lathe the support you put it on is very important. A flimsey bench can reduce the usefullness of your lathe and a heavy one can improve its performance. Even small 6″ (150mm) lathes benefit from a heavy steel stand. The one built for my 6″ Craftsman weighs 3 or 4 times as much as the lathe and includes a chip pan.

References and Links

The Engine Lathe King of machine tools. Do you need one in your blacksmith shop?

MACHINERY’S HANDBOOK, Industrial Press