Really Stupid Gas Burner

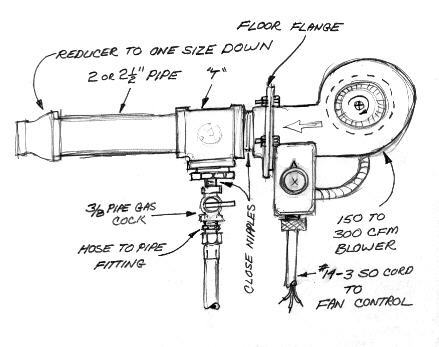

NOTE: These burners require NO precision gas orifices and NO special nozzles. Just dump the gas in the air flow!

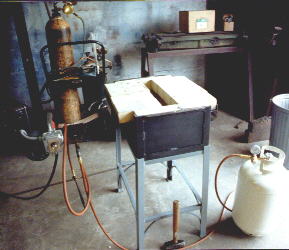

Photo of gas forge in 1985 (c) Jock Dempsey This is a “trough” or “trench” style forge I built after seeing one similar to it in California. It got hot enough to weld but pieces dropped into it were hard to retrieve. The burner assembly was identical as above except it attached with a union so it was easy to remove. The “nozzle” on this forge was shaped from the bricks and some refractory cement. I used this forge for one job and then scrapped it. Parts of it have been recycled onto my new forge. The components of the burner needed a “heat shield” between them and the forge. After a few hours of use the outside of this forge was practically glowing red hot! A piece of sheet metal set a few inches away from the forge would have reflected and absorbed the radiant heat.

All the materials for this forge were purchased new (including steel and bricks) and cost $407 US in 1985. That included the cylinders and a $50 container of refractory cement that only 10% was used. The forge alone cost about $225 US. You can do a lot better with scrounged materials.